Detailing Chemistry 101: The Power of pH in Detailing Chemicals

April 12, 2023

What is pH?

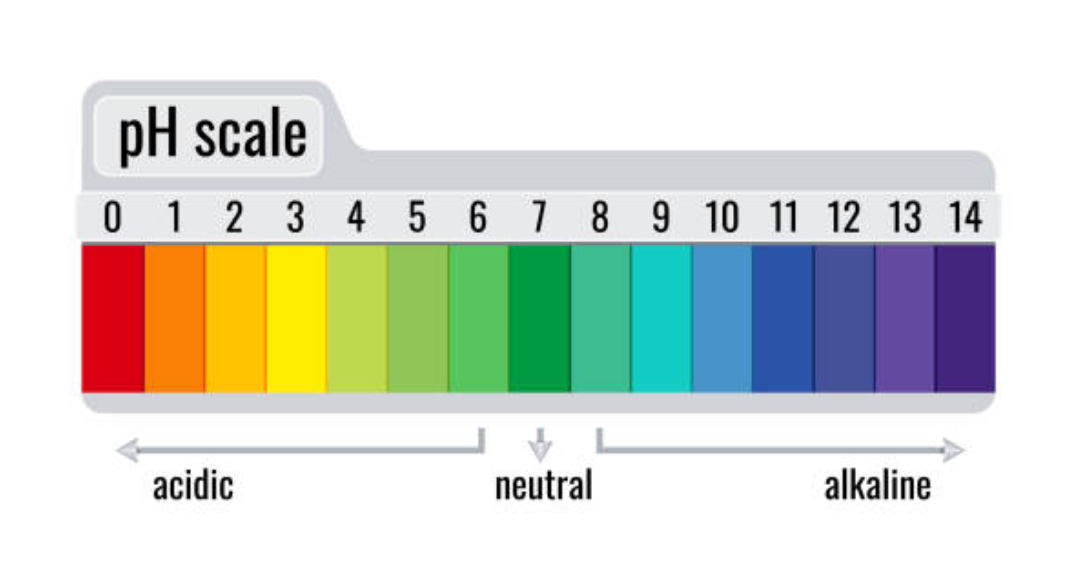

Before diving in to how pH affects common detailing chemicals, it's important to understand what pH is. pH measures the presence of the hydrogen ion, simply put as the acidity or alkalinity of a substance. pH is measured on a scale from 0 to 14, with 0 being the most acidic, 7 being neutral and 14 being the most basic or alkaline. This scale is logarithmic, meaning that each whole increment on the scale increases or decreases acidity or alkalinity by a factor of ten.

What effect does pH have on detailing chemicals?

The cleaning power of detailing chemicals are greatly influenced by pH level. Chemicals all fall into the category of acidic, neutral or alkaline. Each category has a specific use and purpose for different aspects of car detailing.

Acidic cleaners, which have a pH under 7 are normally used in order to remove mineral deposits such as hard water spots. Other chemicals that are normally acidic include acidic wheel cleaners and rust removers.

Neutral cleaners have a pH of 7, meaning they are not acidic nor alkaline. pH neutral cleaners are great for delicate surfaces like the inside of a car, leather or car washing.

Alkaline cleaners have a pH above 7, making them effective at degreasing and cleaning dirt off surfaces. Cleaners with high alkalinity are good for cleaning wheels, tires and engine bays.

Why is it important to use pH neutral cleaners?

In many cases, it's important to use pH neutral cleaners in order to preserve the condition of delicate materials and surfaces on your vehicle. Using a pH that is too high or too low can cause damage to vehicle paint and other surfaces.

Paint is likely to suffer from low pH cleaners. They eat away at a vehicle's clear coat, potentially leading to premature clear coat failure, causing dullness, discoloration and pitting. High pH cleaners can cause paint to become faded and chalky.

Chrome is another surface that can be damaged by extremely high or low pH levels. Acidic cleaners can cause corrosion in chrome, causing pitting and discoloration. High pH chemicals can cause chrome to lose its shine.

Rubber is known to become brittle from use of acidic chemicals. Alkaline chemicals can cause rubber to become less elastic and age prematurely. pH neutral cleaners are the best way to protect rubber surfaces.

Plastic is extremely notorious for damage caused by high or low pH chemicals. Acid can cause cracking of plastics. Basic chemicals are known to discolor and fade plastics.

Using neutral chemicals on these surfaces can ensure that they hold up better over time. High or low pH cleaners can damage surfaces that could otherwise be cleaned by pH neutral sanitation methods.

Addressing Problems and Best Practices

While avoiding the misuse of high or low pH chemicals is the best step in avoiding damage or error, there are ways of minimizing damage caused by certain chemicals.

Using too much of an alkaline product can cause sticking of the product onto a surface, leaving a chalky, streaky film. Following the manufacturer's instructions on proper use will ensure that the chemical will remain effective after some possible neutralization while avoiding leftover residue.

This same practice also applies to acidic chemicals which could damage the exterior appearance of a vehicle. Finding the correct dilution as recommended and should ensure the best results.