How to Remove Sticky Pollen from Your Car This Spring

April 7, 2022

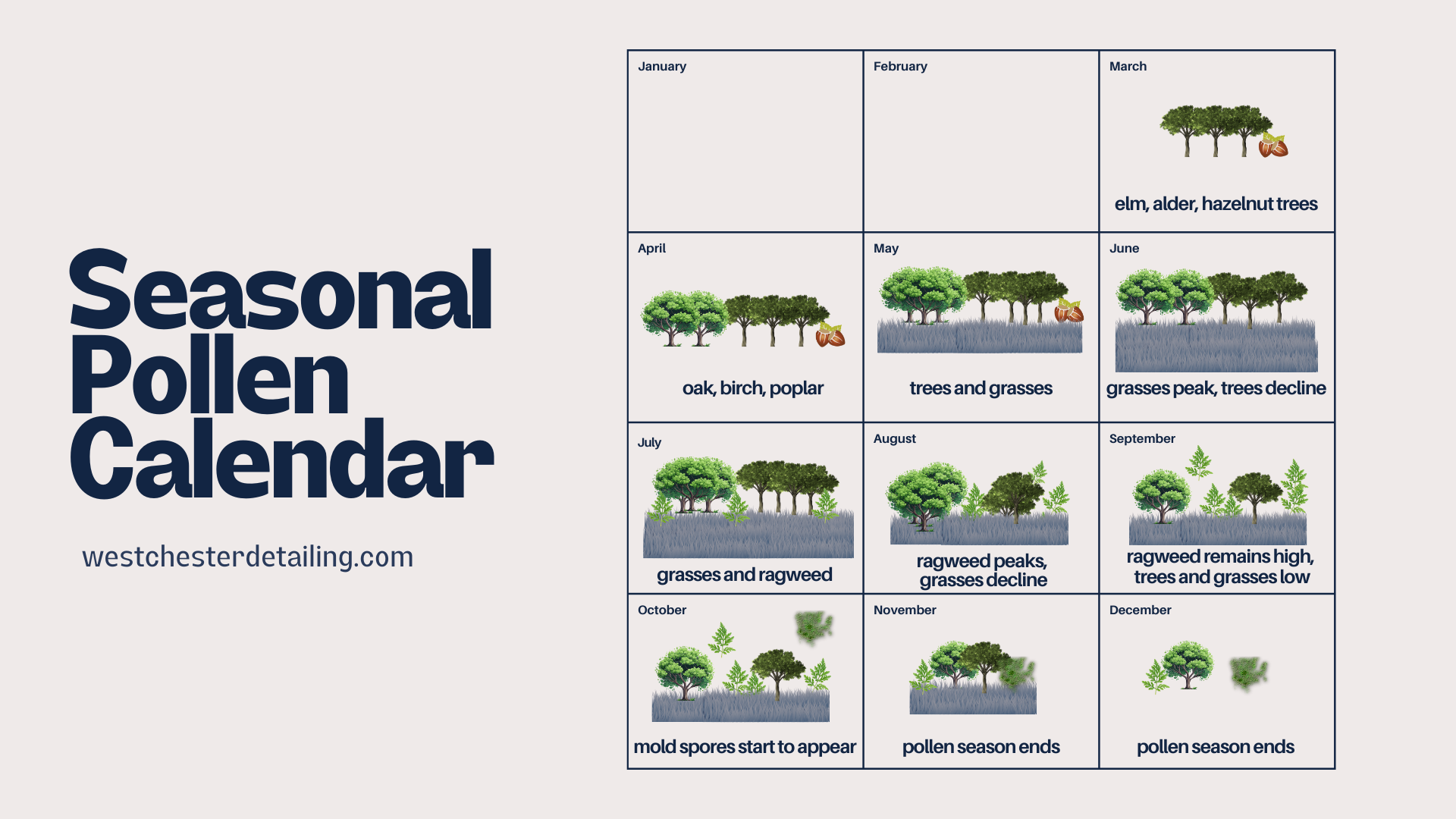

Pollen can be extremely damaging to your vehicle's exterior and interior if proper precautions are not taken. During peak pollen season in the spring and summer, pollen grains released by trees, grasses, and weeds can wreak havoc on your car. As the wind carries pollen through the air, it sticks to any surface it comes into contact with, including your car's paint, glass, and chrome trim.

The tiny, microscopic spines on each pollen grain act like glue, allowing it to adhere tightly to your car's surfaces. Over time, a thick layer of pollen accumulation can occur if your car is not washed regularly. This sticky pollen layer can eat away at your paint finish. The acids in pollen corrode and stain the clear coat, causing dull, faded patches to appear. If left for extended periods, pollen can even penetrate down to the base paint layer leading to oxidation damage.

Aside from paint damage, built-up pollen also reduces visibility through your car's windows and lights. Thick pollen coatings on the glass lead to poor visibility which can be dangerous when driving. It also detracts from your car's overall aesthetic appearance.

Additionally, pollen that gets sucked into your car's AC vents and ventilation system can clog filters and restrict airflow. Pollen essentially chokes the cabin air filter, preventing it from doing its job of removing allergens and pollutants from entering your car. With reduced ventilation, your AC performance deteriorates leading to stuffy air and bad odors inside the cabin. People with pollen allergies may also experience aggravated allergy symptoms from pollen particles blowing out through the AC vents.

To prevent pollen damage, it's important to wash your car frequently during pollen season. Using a typical car shampoo with a microfiber mitt helps lift away pollen particles without scratching the paint. Focus on getting into crevices where pollen accumulates. Rinsing thoroughly carries away the washed-off pollen.

While some automotive shampoos claim to have special pollen-fighting ingredients, regular car shampoos containing surfactants to capture and solubilize pollen are usually adequate for removing pollen. The mechanical act of washing plays a bigger role than any special chemical ingredients. Just be sure to use a pH-balanced soap that won't damage your car's paint.

After washing, inspect closely and spot-clean any remaining pollen deposits. Quickly drying with a microfiber towel prevents water spots. Consider applying a wax or ceramic coating to add further protection against pollen sticking to the paint. Consistent washing and pollen prevention maintenance will keep your car's exterior in great shape all season long

For interior protection, make sure to replace your cabin air filter per the manufacturer's recommendations, usually every 12,000 miles or 12 months. A clean filter prevents pollen and allergens from circulating through your AC system. Deep cleaning your car's interior including vacuuming upholstery, wiping down surfaces, and using an air purifier also helps keep pollen at bay inside your car's cabin.

With consistent washing and pollen-blocking maintenance, you can keep your car looking great and minimize allergic reactions during the high pollen seasons. Protecting your paint finish and cabin air quality from pollen damage allows you to enjoy your vehicle without worrying about faded paint, poor visibility, or stuffy airflow. Work pollen prevention steps into your regular car maintenance routine. It takes some diligence to combat pollen's adhesive properties, but the cleaning and protection efforts pay off in maintaining your car's optimal function and appearance.